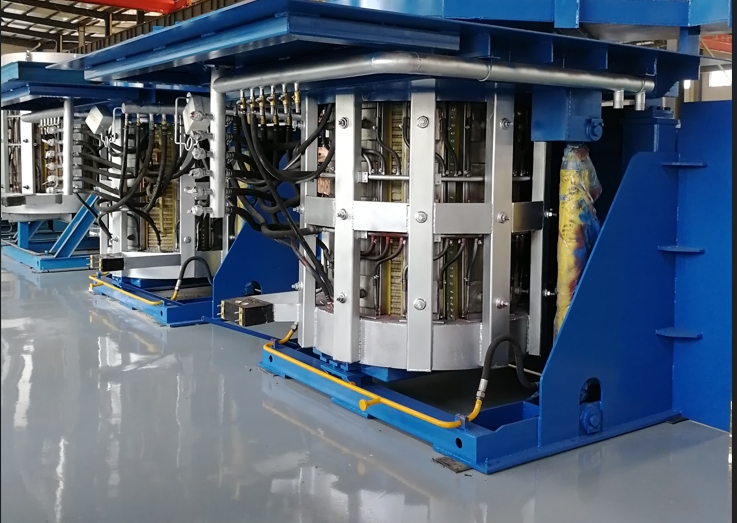

A vacuum induction alloy melting furnace is a device that uses electromagnetic induction to generate eddy

current heat in metal materials in a vacuum environment to melt them, and then generates alloys with precisely

controlled composition through electromagnetic stirring. Mainly used for melting and processing metal materials

(such as stainless steel, nickel based alloys, copper, alloy steel, nickel cobalt alloys,

rare earth neodymium iron curium, etc.) under vacuum or protective atmosphere conditions.

It can also be used for vacuum refining and precision casting of alloy steel.

Due to the ease of removing nitrogen, hydrogen, oxygen, and carbon dissolved in steel and alloys

to much lower levels than smelting at normal pressure under vacuum, impurities such as copper,

zinc, lead, antimony, bismuth, tin, and arsenic with higher vapor pressures than the base metal

at the melting temperature can be removed by volatilization, and the composition of active elements such

as aluminum, titanium, boron, and zirconium that need to be added to the alloy is easy to control. Therefore,

metal materials melted by vacuum induction can significantly improve toughness, fatigue strength,

corrosion resistance, high-temperature creep performance, and magnetic permeability of magnetic alloys, among other properties