New equipment for amorphous strip material - Medium frequency heating bottom casting furnace

Before introducing the bottom casting furnace, let's first introduce the working

process and requirements of the spray coating equipment for amorphous strip.

As is well known, the quality of amorphous strip is closely related to the liquid

level and temperature of the molten steel in the spray bag.

The more stable the temperature and liquid level of the molten steel in the spray bag,

the better the quality of the sprayed strip.

In the process of spraying amorphous strip, the traditional intermediate

ladle cannot provide insulation effect on the molten steel and

cannot effectively spray and stabilize the liquid level of the molten steel.

Therefore, in order to solve the problem of maintaining a

constant temperature and liquid level of the molten steel during the spraying process,

our company has specially developed this equipment - an intermediate frequency heating bottom casting furnace.

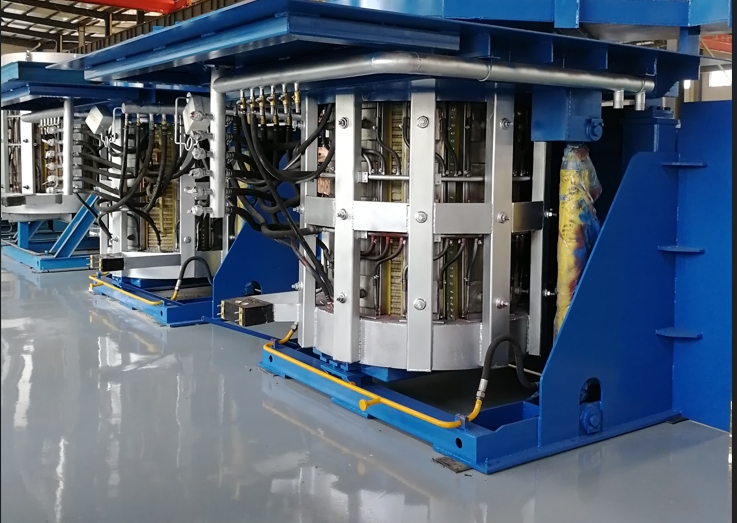

The medium frequency heating bottom casting furnace is used to insulate

the molten steel in the bottom casting furnace through medium frequency heating,

and is equipped with a unique bottom tapping method of the furnace body to

facilitate the injection of molten steel into the ladle at any time; The bottom

casting furnace is usually used in conjunction with our company's ordinary melting furnace.

The bottom casting furnace body is placed on a movable trolley

and equipped with functions of rising, falling, and moving left and right. In other words,

the bottom casting furnace system can move up and down, left and right,

and forward and backward, and the bottom steel outlet of the bottom casting

furnace can be appropriately matched to the position of the spray nozzle in all directions.

The intermediate frequency heating system has the advantages of high power factor,

energy saving, and environmental protection. The key is that the intermediate

frequency heating bottom casting furnace can achieve insulation of the molten steel

in the furnace body, so that the temperature of the molten steel injected into

the spray bag is always maintained within the set temperature range;

Equipped with a dedicated plug mechanism, the opening of the plug can be fine tuned

through a servo system according to the changes in the liquid level of the

molten steel in the spray bag, in order to achieve continuous flow of molten steel

and ensure that the liquid level of the spray bag is basically stable. So,

the medium frequency heating bottom casting furnace can effectively solve the problem

of constant temperature and liquid level of molten steel in the spray ladle,

so the quality of the processed amorphous strip is also compromised,

and the power factor is high, energy-saving and environmentally friendly.

The medium frequency heating bottom casting furnace is usually used in

conjunction with our company's melting furnace.

After the melting furnace has melted the molten steel, the bottom casting

furnace trolley is started to reach the steel receiving position,

and the molten steel in the melting furnace is poured into the bottom casting furnace.

The bottom casting furnace starts the medium frequency heating to raise and keep

the temperature of the molten steel in the furnace. When the trolley is driven to

the spraying position, the steel outlet of the bottom casting furnace and

the opposite end of the spraying nozzle are operated by adjusting the rise,

fall, and left and right movement of the furnace body.