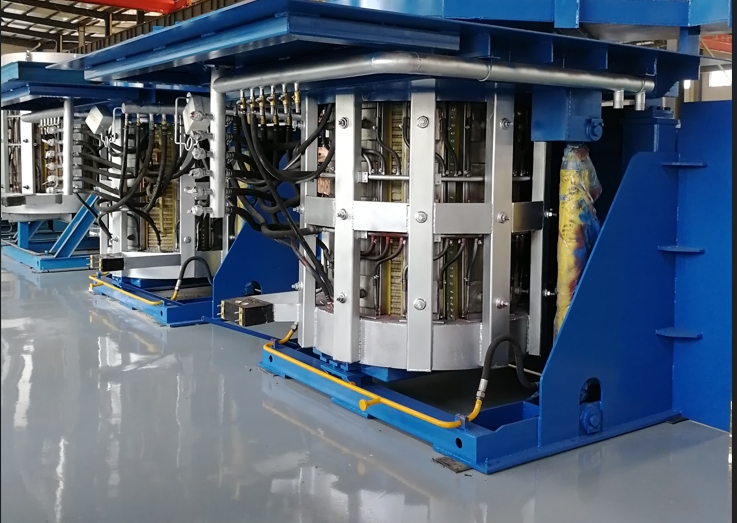

Working principle of intermediate frequency bottom pouring furnace:

The intermediate frequency bottom pouring furnace is equipped with insulation refractory material pouring bags inside, and the molten iron flows out of the pouring bag through the annular gap between the refractory plug rod and the plug cup immersed in the molten iron, achieving pouring and filling. The size of the annular gap determines the speed of pouring. The adjustment of clearance can be achieved through an electric (or manual) reducer and a trapezoidal threaded screw for actual stepless variable adjustment. The cylinder (or lever mechanism) controls the up and down movement of the plunger, thereby controlling the outflow and blockage of molten iron during pouring. A large car with horizontal left and right and front and rear directions, and a small car that can control the pouring port to align with the pouring cup, or discharge the low-temperature molten iron in the pouring ladle into the emergency molten iron ladle next to it and pour it back into the electric furnace.